CASE STUDY: Confined Space Electrical Equipment Installation

IDI Services Delivers Specialised Lifting for Grants Electrical at Longmorn Distillery

Client Profile

Grants Electrical, a leading electrical engineering contractor serving Scotland’s industrial and commercial sectors, required the installation of critical electrical panels and switchgear at Longmorn Distillery in Elgin. As part of a major electrical infrastructure upgrade at this renowned Speyside distillery, Grants Electrical needed a lifting partner with specialised equipment and confined space expertise to safely manoeuvre substantial electrical cabinets through restricted access routes and position them with precision in an underground plant room—all whilst working within an operational distillery environment and maintaining strict safety protocols.

The Challenge

The Longmorn Distillery electrical panel installation presented multiple complex challenges that demanded IDI Services’ specialised expertise:

Access and Space Constraints

- Electrical panels required installation in an underground plant room with severely restricted access routes.

- Narrow corridors, doorways, and low ceiling heights created significant manoeuvring challenges for large equipment.

- Multiple electrical cabinets, each measuring approximately two metres in height and weighing several hundred kilograms.

- Access route through distillery facility requiring careful protection of existing infrastructure and finishes.

- Confined working space within the underground plant room limiting equipment positioning options.

- Limited turning radius in corridors necessitating precise movement control and specialized handling techniques.

Equipment Specifications and Handling Requirements

- Multiple electrical panels and switchgear cabinets requiring damage-free transportation and positioning.

- Sensitive electronic components demanding careful handling throughout all lifting and movement operations.

- Heavy steel construction requiring appropriate lifting equipment and load management.

- Precise positioning requirements to align panels with predetermined mounting locations and cable entry points.

- Protection of panel surfaces, doors, and components during transport through confined spaces.

- Sequential installation of multiple units requiring efficient turnaround and workspace management.

Operational Environment Factors

- Active distillery operations requiring strict safety protocols and minimal disruption to production activities.

- Coordination with Grants Electrical installation team and distillery operations personnel.

- Underground plant room environment with limited ventilation and lighting requiring additional safety measures.

- Ground-level outdoor lifting operations transitioning to confined space underground installation.

- Weather considerations for outdoor telehandler operations and equipment protection.

- Tight project timeline aligned with distillery’s electrical infrastructure upgrade schedule.

Technical Complexity

- Combination of lifting techniques required, including telehandler operations for initial lifts and jacking/skating systems for confined space movement.

- Precise load calculations and centre of gravity assessments for safe handling of tall, narrow electrical cabinets.

- Floor loading considerations in underground plant room ensuring structural capacity for heavy equipment placement.

- Protection systems required for building surfaces, doorways, and existing electrical infrastructure during equipment movement.

- Sequential coordination between outdoor lifting, transport through access routes, and final positioning in plant room.

The Solution

IDI Services designed a comprehensive multi-phase lifting solution leveraging our 45+ years of industry experience:

Phase 1: Pre-Installation Assessment and Planning

Our team conducted thorough surveys and detailed planning to address the project’s unique challenges:

- Comprehensive site survey of Longmorn Distillery documenting all access routes from outdoor delivery point to underground plant room.

- Detailed measurements of doorways, corridors, ceiling heights, turning radii, and floor conditions throughout the access route.

- Assessment of electrical panel specifications, including dimensions, weights, lifting points, and handling sensitivities.

- Development of equipment movement strategy combining telehandler lifting, manual handling, and jacking/skating techniques.

- Load calculations and structural assessments for underground plant room floor loading and panel positioning.

- Creation of comprehensive method statements and risk assessments specific to confined space operations and distillery environments.

- Coordination meetings with Grants Electrical engineering team establishing installation sequences and quality requirements.

- Establishment of communication protocols between all parties to ensure coordinated operations throughout the project.

Phase 2: Specialised Equipment Mobilisation

IDI Services deployed a carefully selected combination of equipment suited to the project’s diverse requirements:

Telehandler Lifting Services:

- Manitou telehandler with appropriate lifting capacity and reach for handling electrical panels at ground level.

- Compact configuration allowing positioning in distillery yard areas whilst maintaining stability for safe lifting operations.

- Hydraulic boom providing controlled load handling for transferring panels from delivery vehicles.

- Specialized lifting attachments and rigging equipment designed for electrical cabinet geometry and lifting points.

- Experienced telehandler operators with distillery sector knowledge and confined space project experience.

Jacking and Skating Systems:

- Hydraulic jacking equipment for controlled elevation of electrical panels enabling skating system installation.

- Heavy-duty skating platforms and rollers designed for multi-hundred-kilogram loads in confined spaces.

- Low-profile skating systems accommodating restricted ceiling heights in underground corridors.

- Precision control mechanisms allowing millimetre-accurate positioning during final placement.

- Load distribution systems protecting floor surfaces and ensuring safe weight transfer throughout movement.

Confined Space Equipment:

- Specialized manual handling equipment for negotiating tight corners and restricted access routes.

- Load monitoring systems ensuring safe working loads throughout all phases of movement.

- Lighting equipment providing adequate visibility in underground plant room and access corridors.

- Communication systems maintaining contact between teams at different project locations.

- Comprehensive PPE and safety equipment meeting confined space and distillery safety requirements.

Protection and Support Systems:

- Door frame protectors, wall padding, and floor protection materials safeguarding distillery infrastructure.

- Equipment covers protecting electrical panels from environmental exposure during outdoor handling.

- Temporary support structures stabilising panels during jacking and skating operations.

- Measurement and alignment tools ensuring precise positioning at final locations.

Phase 3: Ground-Level Reception and Initial Handling

The project commenced with outdoor lifting operations:

Delivery Reception:

- Coordination with Grants Electrical regarding panel delivery schedules and unloading sequences.

- Telehandler positioning in distillery yard providing optimal access to delivery vehicles.

- Safety zone establishment around lifting operations protecting personnel and distillery activities.

- Weather assessment ensuring suitable conditions for outdoor lifting and equipment protection.

Telehandler Lifting Operations:

- Controlled unloading of electrical panels from delivery vehicles using telehandler and specialized rigging.

- Careful handling of tall, narrow cabinets maintaining stability and preventing tipping during lifts.

- Transfer of panels to staging area near underground plant room access point.

- Sequential handling of multiple units maintaining efficient workflow and minimizing outdoor exposure time.

- Protection of panel surfaces during outdoor operations and transfer to indoor access routes.

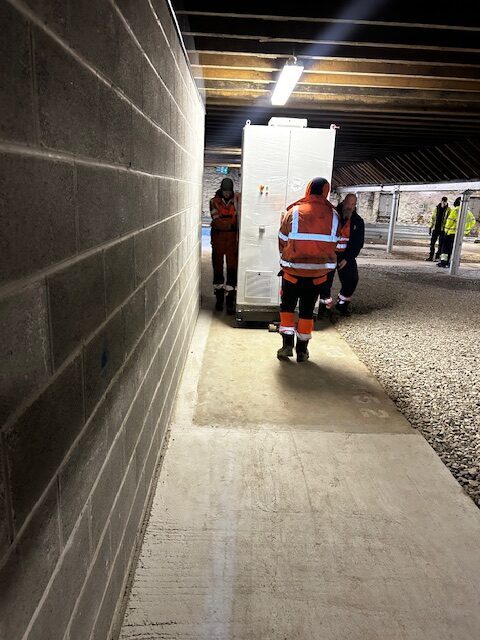

Phase 4: Confined Space Movement and Navigation

The critical phase involved manoeuvring panels through severely restricted access routes:

Access Route Navigation:

- Transition of electrical panels from ground-level staging area to underground access corridor entrance.

- Installation of comprehensive protection systems along the movement route safeguarding walls, doorframes, and existing equipment.

- Careful manoeuvring through narrow doorways requiring precise positioning and, in some cases, panel orientation adjustments.

- Navigation of corridor turns using combination of manual handling and mechanical assistance.

- Continuous monitoring of clearances ensuring safe passage without contact with building surfaces.

Jacking and Skating Operations:

- Strategic deployment of jacking systems elevating panels for skating platform installation.

- Precise load positioning on skating systems ensuring balanced weight distribution and stability.

- Controlled movement through underground corridors using skating systems’ low-profile, high-capacity design.

- Millimetre-accurate manoeuvring through restricted spaces requiring exceptional operator skill and coordination.

- Sequential movement of multiple panels through the same confined access route demonstrating operational efficiency.

Phase 5: Precision Installation in Plant Room

The final phase achieved exact positioning in the underground facility:

Plant Room Operations:

- Coordination with Grants Electrical team regarding specific positioning requirements for each electrical panel.

- Assessment of floor conditions and structural mounting points in underground plant room.

- Precise positioning using skating systems to align panels with predetermined locations.

- Fine adjustments achieving millimetre-accurate placement for cable entry points and mounting bolt alignments.

- Careful lowering and securing of panels onto permanent mounting positions.

- Sequential installation of multiple units creating organized rows of electrical switchgear as visible in final configuration.

Quality Verification:

- Verification of panel positioning meeting Grants Electrical specifications and alignment requirements.

- Inspection confirming no damage to panels, components, or finishes throughout handling and installation processes.

- Documentation of final positions and handover to Grants Electrical for connection and commissioning activities.

Phase 6: Project Completion

- Systematic removal of all protection systems, jacking equipment, and skating platforms from access routes and plant room.

- Site reinstatement ensuring underground facility and access corridors left in pristine condition.

- Comprehensive project documentation with photographic records of installation sequence and final positioning.

- Final coordination meeting with Grants Electrical and distillery management confirming successful completion.

The Results

The Grants Electrical project at Longmorn Distillery was completed with exemplary outcomes:

Safety Performance

- Zero safety incidents throughout all confined space operations, lifting activities, and equipment manoeuvring.

- Full compliance with confined space regulations, distillery safety protocols, and electrical installation requirements.

- Comprehensive risk management addressing all aspects of underground operations and restricted access challenges.

- Exemplary coordination between outdoor lifting operations and confined space installation activities.

- Professional execution maintaining highest safety standards in challenging operational environment.

Operational Excellence

- On-time completion meeting Grants Electrical installation schedule and distillery’s electrical infrastructure timeline.

- Zero damage to electrical panels, switchgear components, or sensitive electronic equipment throughout all handling phases.

- No impact on distillery infrastructure, including walls, doorframes, floors, or existing electrical systems.

- Successful navigation of severely restricted access routes without incident or delay.

- Minimal disruption to distillery operations through efficient execution and careful coordination.

Technical Achievement

- Precision positioning of all electrical panels achieving exact alignment with mounting points and cable entry locations.

- Successful confined space operations demonstrating expertise in challenging underground installations.

- Effective combination of telehandler lifting, jacking systems, and skating techniques for optimal results.

- Sequential installation efficiency moving multiple heavy panels through same restricted access route.

- Complete protection of equipment and facility throughout all phases of the project.

Client Satisfaction

- Seamless partnership with Grants Electrical engineering team throughout planning and execution phases.

- Flexible coordination accommodating installation schedules and distillery operational requirements.

- Professional communication maintaining clear updates throughout all project phases.

- Quality delivery meeting exacting standards expected in critical electrical infrastructure projects.

Client Testimonial

“IDI Services demonstrated exceptional capability in managing the confined space installation of electrical panels at Longmorn Distillery. Their combination of telehandler operations, jacking and skating techniques, and confined space expertise provided exactly the solution we needed for this challenging project. The team’s careful handling of sensitive electrical equipment, precise positioning in the underground plant room, and commitment to safety ensured the installation proceeded flawlessly. Their professionalism and technical skill made them the ideal partner for this critical infrastructure upgrade.”

— Project Manager, Grants Electrical

The IDI Advantage

This successful project exemplifies IDI Services’ core strengths in confined space operations and distillery sector specialization:

Confined Space Expertise

- 45+ years of experience managing complex installations in restricted access environments.

- Specialized techniques combining multiple handling methods for optimal solutions in challenging spaces.

- Comprehensive safety protocols ensuring full compliance with confined space regulations and best practices.

- Technical proficiency navigating underground facilities, narrow corridors, and restricted access routes.

Multi-Discipline Capabilities

- Telehandler operations providing efficient ground-level lifting and initial handling.

- Jacking and skating systems enabling precise movement in confined spaces where traditional lifting equipment cannot operate.

- Manual handling expertise complementing mechanical systems for optimal control in restricted areas.

- Flexible equipment selection choosing appropriate tools and techniques for each phase of complex projects.

Distillery Sector Specialization

- Extensive experience across Scotland’s distilling industry, including major Speyside facilities like Longmorn.

- Understanding of distillery operations and infrastructure requirements for electrical, process, and production systems.

- Established relationships with leading contractors serving the distillery sector, including Grants Electrical.

- Compliance expertise with stringent distillery safety standards and operational protocols.

Electrical Equipment Handling

- Proven capabilities installing electrical panels, switchgear, transformers, and control systems.

- Sensitivity awareness protecting electronic components and sensitive equipment throughout all operations.

- Precision positioning achieving exact alignment for electrical connections and mounting requirements.

- Quality assurance maintaining equipment integrity from initial handling through final installation.

Client-Focused Approach

- Collaborative planning working closely with electrical contractors and facility operators.

- Flexible scheduling accommodating installation timelines and operational requirements.

- Clear communication throughout all project phases ensuring alignment with expectations.

- Reliable delivery meeting critical deadlines for infrastructure upgrade projects.

Distillery Infrastructure Projects

Scotland’s distilling industry requires lifting partners who understand the unique challenges of working within historic facilities whilst installing modern infrastructure. IDI Services brings proven capabilities:

Electrical System Projects

- Electrical panels, switchgear, and distribution equipment installation.

- Transformer and power supply system positioning.

- Control system and automation equipment handling.

- Emergency power and backup system installations.

Confined Space Operations

- Underground plant rooms and basement facilities.

- Historic building renovations with restricted access.

- Multi-floor installations through narrow stairwells and corridors.

- Rooftop equipment access through limited openings.

Complete Service Portfolio

- Contract lifting using diverse equipment configurations.

- Jacking and skating for confined space applications.

- Telehandler operations for ground-level handling.

- Multi-phase projects combining multiple handling techniques.

Why Choose IDI Services for Confined Space Electrical Installations

Electrical infrastructure projects in distillery environments demand lifting partners who combine technical expertise with confined space proficiency and operational sensitivity. IDI Services delivers:

- Confined space specialization with comprehensive experience in underground and restricted access installations.

- Multi-technique capabilities, including telehandlers, jacking systems, skating equipment, and manual handling.

- Distillery sector expertise understanding operational requirements and safety protocols.

- Safety-first culture with zero-incident performance record in challenging environments.

- Precision execution achieving exact positioning for critical electrical equipment.

- Proven reliability delivering complex projects on time and to specification.

Whether your project involves electrical panels, switchgear, transformers, or any equipment requiring installation in confined spaces, underground facilities, or restricted access areas within distillery or industrial environments, IDI Services delivers the expertise, equipment, and execution excellence that industry leaders like Grants Electrical depend on.

For more information on how IDI Services can support your confined space lifting and electrical equipment installation requirements, contact our team today.