CASE STUDY: Heavy Subsea Structure Transport

IDI Services Delivers SPMT Operations for Dale’s Engineering Peterhead

Client Profile

Dale’s Engineering, a leading fabricator of subsea structures and equipment for the offshore energy sector, required the transportation of multiple 200-tonne subsea structures from their Peterhead fabrication facility to the quayside approximately one mile away. As a specialist in complex offshore equipment manufacturing, Dale’s Engineering needed a transport partner with the technical expertise, specialised equipment, and logistical capabilities to safely move these substantial structures through public roads, coordinate with authorities, and deliver them to the quayside for onward shipment—all whilst maintaining strict safety standards and minimising disruption to the local community.

The Challenge

The Dale’s Engineering subsea structure transport presented multiple complex challenges that demanded IDI Services’ specialised expertise:

Load Specifications and Characteristics

- Multiple subsea structures, each weighing 200 tonnes, requiring careful handling and transport planning.

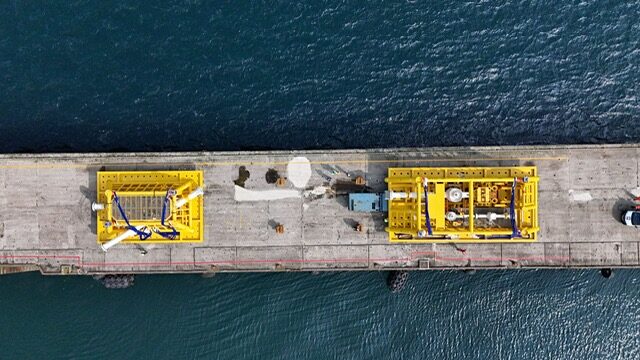

- Large yellow steel frame structures with complex geometries and multiple protruding components.

- Substantial dimensions creating abnormal load classifications requiring special permits and routing.

- High-value fabricated equipment representing significant investment and requiring damage-free delivery.

- Structural integrity considerations throughout transport to prevent distortion or stress to welded connections.

Route and Infrastructure Challenges

- One-mile transport route through Peterhead’s public roads requiring comprehensive traffic management.

- Route survey and assessment necessary to identify potential obstacles, clearances, and load-bearing capacities.

- Multiple road junctions, roundabouts, and potentially restricted areas along the transport corridor.

- Coordination with local authorities for road closures, traffic management, and permit requirements.

- Public safety considerations requiring professional escort services and clear communication with residents and businesses.

- Coastal environment factors, including wind exposure during quayside operations.

Technical Transport Requirements

- Self-Propelled Modular Transporters (SPMTs) necessary for controlled movement of 200-tonne loads.

- Precise load positioning and weight distribution calculations for optimal SPMT configuration.

- Multiple structures requiring sequential transport operations with efficient turnaround times.

- Ground conditions assessment at both Dale’s yard and quayside to ensure safe operations.

- Load securing systems to prevent movement during transport whilst protecting structure surfaces.

Operational Coordination

- Escort vehicle requirements, including pilot vehicles and rear escorts for abnormal load movements.

- Police coordination for road closures and traffic management along the transport route.

- Communication with local businesses and residents regarding temporary road access restrictions.

- Weather monitoring for safe transport conditions, particularly wind considerations for large structures.

- Coordination with port authorities and marine operations at the quayside destination.

- Sequential scheduling to maintain Dale’s Engineering production and delivery commitments.

The Solution

IDI Services designed a comprehensive SPMT transport solution leveraging our 45+ years of industry experience:

Phase 1: Comprehensive Planning and Route Assessment

Our team conducted extensive pre-project planning to ensure flawless execution:

- Detailed survey of the one-mile transport route from Dale’s yard to Peterhead quayside, documenting road widths, junction geometries, overhead clearances, and surface conditions.

- Engineering assessment of subsea structure specifications, including dimensions, weights, centre of gravity locations, and lifting point configurations.

- Load calculations and SPMT configuration planning to achieve optimal weight distribution and stability during transport.

- Development of comprehensive method statements and risk assessments specific to abnormal load operations through populated areas.

- Coordination meetings with Aberdeenshire Council, Police Scotland, and port authorities to secure necessary permits and approvals.

- Route familiarisation exercises identifying potential obstacles and establishing contingency procedures.

- Communication plan development for notifying residents, businesses, and stakeholders along the transport corridor.

Phase 2: Specialised Equipment Mobilisation

IDI Services deployed sophisticated heavy transport equipment suited to 200-tonne subsea structure movements:

Self-Propelled Modular Transporters (SPMTs):

- Fleet of Sarens-manufactured SPMTs configured specifically for the subsea structures’ weight and dimensions.

- Multi-axle modular platform providing controlled, precise movement with hydraulic suspension systems.

- Independent wheel steering allowing precise manoeuvring through tight junctions and turns.

- Hydraulic load levelling systems maintaining structure stability throughout the transport operation.

- Remote control operation enabling optimal positioning and fine adjustments during loading and unloading.

- Real-time load monitoring systems tracking weight distribution and ensuring safe working parameters.

Load Securing and Protection Systems:

- Custom-designed securing arrangements for the specific geometry of each subsea structure.

- Protective materials preventing surface damage during transport whilst maintaining secure attachment.

- Anti-slip systems ensuring load stability throughout the journey.

- Structural support points designed to prevent distortion during transport operations.

Escort and Safety Vehicles:

- IDI Services pilot vehicles positioned ahead of the abnormal load to manage traffic flow and identify potential issues.

- Rear escort vehicles protecting the transport from following traffic and managing junction crossings.

- Police escort coordination ensuring authority and public safety throughout the operation.

- Communication systems linking all vehicles for coordinated movement and immediate response to changing conditions.

- Signage and lighting systems ensuring maximum visibility and public awareness.

Support Equipment and Personnel:

- Experienced SPMT operators with extensive abnormal load transport expertise.

- Qualified banksmen coordinating movement through restricted areas and junctions.

- Engineering support personnel monitoring structural and load conditions throughout transport.

- Traffic management teams ensuring safe operations at critical points along the route.

Phase 3: Loading Operations at Dale’s Yard

The initial phase involved safe transfer of subsea structures onto the SPMT systems:

Yard Preparation:

- Assessment and preparation of ground conditions at Dale’s fabrication yard for SPMT positioning.

- Coordination with Dale’s Engineering production team regarding structure readiness and lifting point accessibility.

- SPMT positioning adjacent to subsea structures with precise alignment for optimal load transfer.

- Final safety briefings with all personnel involved in loading operations.

Structure Loading:

- Controlled lift and positioning of 200-tonne subsea structures using appropriate lifting equipment in coordination with SPMT operations.

- Precise placement onto SPMT platform with careful attention to weight distribution and centre of gravity.

- Load securing procedures ensuring structural stability during transport.

- Comprehensive pre-departure inspections verifying load security, SPMT systems, and all safety equipment.

- Final measurements confirming structure positioning and overall transport configuration within regulatory limits.

Phase 4: Road Transport Operations

The critical transport phase required meticulous coordination and execution:

Pre-Departure Coordination:

- Final briefings with all escort vehicle personnel, SPMT operators, and support teams.

- Confirmation of road closure authorisations and traffic management arrangements.

- Weather assessment ensuring suitable conditions for transport of large structures.

- Communication with port authorities confirming quayside readiness for structure delivery.

Controlled Transport Execution:

- Convoy departure from Dale’s yard with police escort, pilot vehicles, SPMT transport, and rear escorts.

- Measured progress through Peterhead’s roads at controlled speeds ensuring load stability and public safety.

- Real-time communication between all convoy members coordinating movements through junctions and turns.

- Traffic management at critical points allowing safe passage whilst minimising public disruption.

- Continuous monitoring of load conditions, SPMT systems, and environmental factors throughout the journey.

- Professional banksmen managing specific manoeuvres through restricted areas or complex junctions.

Public Interface Management:

- Clear signage and professional conduct maintaining positive community relations.

- Minimal disruption protocols respecting local businesses and residents along the route.

- Flexible scheduling accommodating peak traffic periods where possible.

- Responsive communication addressing any public concerns or queries during operations.

Phase 5: Quayside Delivery and Positioning

The final phase involved precision placement at Peterhead quayside:

Quayside Operations:

- Controlled entry onto quayside areas with assessment of surface conditions and load-bearing capacity.

- Coordination with port operations and marine traffic ensuring safe positioning activities.

- Precise manoeuvring of SPMTs to position subsea structures at designated locations for crane lifting or direct vessel loading.

- Fine positioning adjustments using SPMT hydraulic systems and steering capabilities.

- Safe offloading or positioning for subsequent lifting operations by marine equipment.

Sequential Operations:

- Efficient turnaround of SPMT systems for return journey to Dale’s yard for additional structures.

- Multiple transport cycles delivering all subsea structures to quayside within project timescale.

- Consistent safety standards and operational procedures across all transport movements.

- Continuous coordination with Dale’s Engineering maintaining production flow and delivery schedules.

Phase 6: Project Completion

- Comprehensive documentation of all transport operations with photographic records and delivery confirmations.

- Demobilisation of SPMT systems and support equipment following final structure delivery.

- Post-project review with Dale’s Engineering and relevant authorities confirming successful completion.

- Handover of all structures at quayside ready for onward shipping operations.

The Results

The Dale’s Engineering subsea structure transport in Peterhead was completed with exemplary outcomes:

Safety Performance

- Zero safety incidents throughout all loading, transport, and delivery operations involving 200-tonne structures.

- Full compliance with abnormal load regulations, traffic management requirements, and public safety protocols.

- Professional execution maintaining the highest safety standards during public road operations.

- Exemplary traffic management ensuring public safety and minimal disruption throughout all transport movements.

- Comprehensive risk management addressing all aspects of heavy structure transport through populated areas.

Operational Excellence

- On-time delivery of all subsea structures meeting Dale’s Engineering production and shipping schedules.

- Zero damage to high-value fabricated structures throughout loading, transport, and quayside delivery.

- Efficient sequential operations transporting multiple 200-tonne structures with minimal turnaround times.

- Successful navigation of the one-mile route through Peterhead’s public roads without incident.

- Seamless coordination with police escorts, traffic management, and port operations throughout the project.

Technical Achievement

- Precision SPMT operations successfully managing 200-tonne loads with complete control and stability.

- Optimal load configurations ensuring safe weight distribution and structural integrity during transport.

- Professional escort services providing comprehensive traffic management and public safety measures.

- Effective route execution navigating junctions, roundabouts, and restricted areas without complications.

- Successful quayside positioning delivering structures to precise locations for onward shipping operations.

Client and Community Relations

- Minimal public disruption through efficient transport operations and clear communication.

- Professional community interface maintaining positive relations with Peterhead residents and businesses.

- Successful authority coordination achieving full regulatory compliance and professional cooperation.

- Client satisfaction meeting Dale’s Engineering expectations for safety, efficiency, and reliability.

Client Testimonial

“IDI Services demonstrated exceptional capability in transporting our 200-tonne subsea structures from our Peterhead facility to the quayside. Their SPMT operations, escort services, and traffic management were executed flawlessly. The team’s coordination with local authorities, professional approach to public road transport, and commitment to safety ensured all structures were delivered on time and without incident. Their expertise in abnormal load operations and understanding of our production requirements made them the ideal partner for this critical logistics operation.”

— Operations Manager, Dale’s Engineering

The IDI Advantage

This successful project exemplifies IDI Services’ core strengths in heavy transport and offshore sector support:

SPMT Transport Expertise

- Extensive experience operating Self-Propelled Modular Transporters for loads up to and exceeding 200 tonnes.

- Technical proficiency in load planning, weight distribution, and SPMT configuration optimisation.

- Proven capabilities transporting subsea structures, offshore equipment, and heavy industrial components.

- Comprehensive fleet access through strategic partnerships with leading SPMT specialists like Sarens.

Abnormal Load Operations

- 45+ years of experience managing abnormal load transport across Scotland and the UK.

- Complete service delivery, including route surveys, permit applications, traffic management, and escort services.

- Authority coordination maintaining excellent relationships with councils, police, and regulatory bodies.

- Professional execution ensuring compliance with all regulations whilst minimising public disruption.

Offshore Sector Specialisation

- Deep understanding of subsea equipment, structures, and offshore sector requirements.

- Established relationships with leading fabricators like Dale’s Engineering and major offshore operators.

- Quayside operations experience coordinating with port authorities and marine logistics.

- Complete logistics solutions from fabrication yard to vessel loading for offshore deployments.

Technical Excellence

- Engineering-led planning ensuring optimal solutions for complex transport challenges.

- Load monitoring systems providing real-time data throughout transport operations.

- Precision positioning delivering structures to exact locations as required by clients.

- Quality assurance maintaining equipment integrity and preventing damage throughout operations.

Client-Focused Approach

- Flexible scheduling accommodating production timelines and shipping requirements.

- Clear communication throughout planning, execution, and completion phases.

- Reliable delivery meeting critical deadlines for offshore project schedules.

- Collaborative partnerships working closely with fabricators, port operators, and authorities.

Peterhead and North East Scotland Expertise

IDI Services maintains a strong operational presence in Peterhead and across North East Scotland, serving the region’s vibrant offshore energy sector:

Regional Capabilities

- Comprehensive knowledge of Peterhead’s infrastructure, port facilities, and road networks.

- Established relationships with Aberdeenshire Council, Police Scotland, and port authorities.

- Rapid mobilisation capabilities for projects across Aberdeen, Peterhead, and surrounding areas.

- Understanding of regional offshore sector requirements and operational priorities.

Diverse Project Experience

- Subsea structures and equipment transport for major fabricators.

- Offshore module movements from fabrication yards to quaysides and vessels.

- Port and terminal equipment handling and positioning.

- Heavy industrial transport supporting oil and gas, renewable energy, and decommissioning sectors.

Why Choose IDI Services for Heavy Subsea Structure Transport

The offshore energy sector demands transport partners who combine technical expertise with operational excellence and unwavering safety standards. IDI Services delivers:

- SPMT transport capabilities for loads ranging from tens to hundreds of tonnes.

- Abnormal load expertise, including route planning, permits, traffic management, and escort services.

- Offshore sector specialisation understanding subsea equipment and fabrication industry requirements.

- Safety-first culture with zero-incident performance record on complex public road operations.

- Complete logistics management from fabrication yard through quayside delivery.

- Proven reliability delivering critical projects on time and to specification.

Whether your project involves subsea structures, offshore modules, heavy equipment, or any substantial fabricated components requiring transport through public areas, IDI Services delivers the expertise, equipment, and execution excellence that industry leaders like Dale’s Engineering depend on.

For more information on how IDI Services can support your heavy transport and SPMT operation requirements, contact our team today.