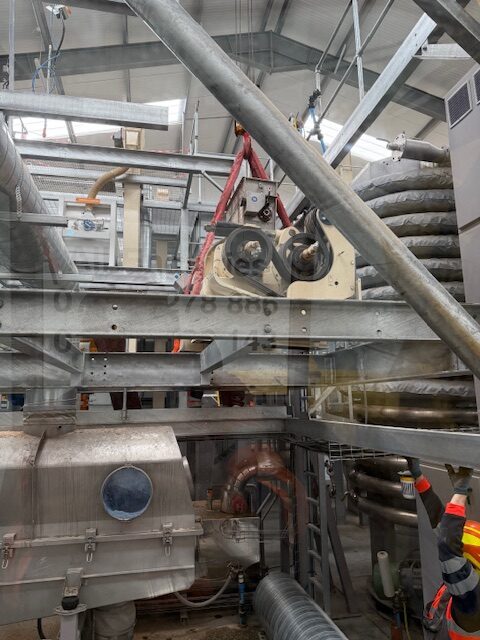

CASE STUDY: Compact Crane Excellence in Industrial Environments

IDI Services Demonstrates Confined Space Lifting Capabilities at Oat Processing Facility

Project Overview

Industrial facilities frequently require lifting operations in spaces where conventional mobile cranes simply cannot access. When a major oat processing mill needed critical steel beam replacements within their production facility, the project demanded specialized equipment capable of operating in severely confined spaces whilst maintaining full lifting capacity and safety standards. This case study demonstrates how IDI Services’ compact crane fleet provides solutions where traditional lifting equipment fails, delivering precision operations in the most challenging industrial environments.

The Challenge

The oat mill steel beam replacement project presented challenges that are increasingly common across Scotland’s industrial sector:

Access and Space Constraints

- Steel beam replacement required within an active oat processing facility with severely restricted access routes.

- Conventional mobile cranes unable to access the interior working area due to doorway widths, ceiling heights, and building configurations.

- Tight working envelope with existing processing equipment, pipework, ductwork, and structural elements creating obstacles.

- Multi-storey facility with steel beam locations at elevated positions requiring precise reach and positioning.

- Limited floor space for crane positioning and outrigger deployment.

- Operational processing equipment requiring protection throughout lifting operations.

Structural Replacement Requirements

- Removal of existing steel beams supporting overhead systems and infrastructure.

- Installation of replacement structural steel maintaining precise alignment and load-bearing specifications.

- Sequential operations requiring removal of old beams followed immediately by installation of new components.

- Heavy steel sections weighing several hundred kilograms requiring controlled lifting at height.

- Precision positioning to align with existing bolt patterns and connection points.

- Minimal disruption to facility operations and production schedules.

Technical Complexity

- Overhead pipework, ductwork, and services creating restricted lift paths requiring careful load trajectory planning.

- Existing structural framework limiting crane boom movement and positioning options.

- Elevated working heights demanding appropriate reach whilst maintaining stability and safe working loads.

- Multiple lift points and orientations throughout the facility requiring crane repositioning.

- Load calculations accounting for building floor loading capacities and structural constraints.

- Coordination with fabrication and installation teams ensuring seamless equipment exchange.

Operational Environment Factors

- Active food processing facility with stringent hygiene and contamination control requirements.

- Production schedules requiring lifting operations during specific maintenance windows.

- Personnel safety considerations with ongoing facility activities in adjacent areas.

- Temperature and environmental controls within the processing facility.

- Floor surface protection preventing damage to specialized industrial flooring systems.

The IDI Services Solution

IDI Services deployed one of our two specialized compact cranes, purpose-built for exactly these challenging confined space scenarios:

Compact Crane Capabilities

Small Footprint, Full Capability:

- Compact tracked excavator-based crane with significantly reduced dimensions compared to conventional mobile cranes.

- Narrow chassis width allowing passage through standard industrial doorways and restricted access routes.

- Low overall height enabling operation within buildings with limited ceiling clearance.

- Tracked undercarriage providing stability and manoeuvrability on industrial floor surfaces.

- Full lifting capacity maintained despite compact configuration, suitable for structural steel and heavy industrial components.

Versatility and Precision:

- Hydraulic boom with multiple articulation points allowing precise load positioning in confined spaces.

- Variable reach capability adapting to different working heights and distances within the facility.

- 360-degree slewing providing complete working envelope coverage from single positioning.

- Precise control systems enabling millimetre-accurate load placement for structural alignment.

- Load monitoring systems ensuring safe working parameters throughout all operations.

Indoor Operation Suitability:

- Compact design enabling operation within industrial buildings where external cranes cannot reach.

- Tracked configuration distributing weight across larger surface area, suitable for industrial flooring.

- Manageable emissions and noise levels appropriate for indoor industrial environments.

- Easy repositioning allowing the crane to move between multiple lift locations within the same facility.

Phase 1: Pre-Project Planning and Assessment

Our team conducted comprehensive planning to optimize the compact crane deployment:

- Detailed facility survey documenting access routes, working areas, ceiling heights, floor conditions, and existing equipment locations.

- Measurement of doorways, corridors, and restricted passages confirming compact crane access feasibility.

- Assessment of steel beam specifications, including dimensions, weights, removal procedures, and installation requirements.

- Lift point identification and load path planning accounting for overhead services and structural obstacles.

- Floor loading calculations ensuring industrial flooring could safely support crane operations.

- Coordination with facility management regarding production schedules and operational windows.

- Development of comprehensive method statements and risk assessments specific to indoor industrial lifting operations.

Phase 2: Equipment Mobilisation and Facility Access

The compact crane’s small footprint enabled seamless facility access:

Facility Entry:

- Compact crane navigated standard industrial doorways that would prevent conventional mobile crane access.

- Tracked configuration allowed controlled movement through facility corridors and production areas.

- Minimal clearance requirements enabling passage beneath overhead services and mezzanine levels.

- Ground protection systems preserving specialized industrial flooring throughout crane movement.

Positioning and Setup:

- Crane positioning within the oat processing facility adjacent to steel beam replacement locations.

- Outrigger deployment in confined space utilizing compact footprint for stability.

- Assessment of overhead clearances ensuring safe boom operation beneath existing structure and services.

- Final safety briefings with facility personnel and installation teams.

Phase 3: Steel Beam Removal Operations

The first phase involved careful removal of existing structural elements:

Existing Beam Assessment:

- Coordination with structural engineers regarding load-bearing implications of beam removal.

- Temporary support systems installed where necessary to maintain structural integrity during replacement.

- Disconnection of existing beam connections under supervision of installation team.

- Rigging of existing steel beams using appropriate sling configurations.

Controlled Removal:

- Precision lifting of existing beams navigating complex overhead pipework and ductwork visible in operational area.

- Careful load trajectory management avoiding contact with processing equipment, services, and structural elements.

- Controlled lowering and removal of old beams from facility maintaining protection of surrounding equipment.

- Sequential removal operations as required by structural replacement phasing.

Phase 4: Replacement Beam Installation

The critical installation phase demonstrated the compact crane’s precision capabilities:

New Beam Positioning:

- Rigging of replacement steel beams with appropriate lifting equipment and load distribution.

- Controlled lift to elevated positions within the facility structure.

- Precise manoeuvring through confined spaces and around obstacles using articulated boom configuration.

- Millimetre-accurate positioning aligning beams with existing bolt patterns and connection points.

Final Installation:

- Incremental adjustments achieving perfect alignment for structural connections.

- Temporary support of beams whilst installation team completed bolting and securing operations.

- Verification of positioning meeting structural specifications and load-bearing requirements.

- Sequential installation of multiple beams as required throughout the facility.

Phase 5: Project Completion

- Systematic repositioning of compact crane to additional locations within facility for further beam replacements.

- Comprehensive site cleanup and removal of ground protection systems.

- Final facility inspections confirming no damage to processing equipment, flooring, or infrastructure.

- Controlled egress of compact crane through facility access routes.

- Project documentation and handover to facility management.

The Results

The oat mill steel beam replacement demonstrated the exceptional value of IDI Services’ compact crane capabilities:

Access Achievement

- Successful facility access through standard industrial doorways where conventional cranes would be impossible to deploy.

- Full operational capability maintained within severely confined industrial environment.

- Multiple positioning locations achieved throughout facility enabling complete project coverage.

- Zero access-related delays demonstrating the compact crane’s fundamental advantage in confined space applications.

Safety Performance

- Zero safety incidents throughout all indoor lifting operations within active food processing facility.

- Full compliance with industrial facility safety requirements and food processing industry standards.

- Complete personnel protection maintaining safety for both lifting team and facility operations staff.

- No damage to processing equipment, services, flooring, or building infrastructure.

Operational Excellence

- Precision positioning achieving exact alignment for structural steel connections.

- Efficient operations completing beam removal and installation within designated maintenance windows.

- Minimal facility disruption maintaining oat mill’s production schedule commitments.

- Seamless coordination with structural installation teams and facility management.

Technical Achievement

- Successful navigation of complex overhead services, including pipework and ductwork throughout working area.

- Load control excellence managing heavy steel beams in confined spaces with restricted lift paths.

- Structural integration achieving perfect alignment with existing connection points and load-bearing requirements.

- Multi-location operations demonstrating crane mobility and repositioning capabilities within facility.

The IDI Advantage: Compact Crane Specialisation

This project exemplifies why IDI Services maintains two specialized compact cranes in our fleet—equipment that provides unique capabilities unavailable from conventional lifting resources:

Where Compact Cranes Excel

Industrial Facility Operations:

- Food processing plants, manufacturing facilities, and production environments requiring internal lifting operations.

- Steel structure maintenance, replacement, and modification within existing buildings.

- Equipment installations in spaces inaccessible to conventional cranes.

- Multi-storey industrial buildings with restricted access routes.

Confined Space Applications:

- Narrow doorways, corridors, and restricted passages preventing conventional crane access.

- Low ceiling environments limiting traditional mobile crane boom operation.

- Dense equipment layouts creating restricted working envelopes.

- Historic buildings with access constraints and structural limitations.

Precision Requirements:

- Structural steel positioning requiring millimetre-accurate alignment.

- Equipment installation within tight clearances and existing infrastructure.

- Load trajectory control navigating complex obstacle fields.

- Sequential operations requiring frequent repositioning within confined areas.

IDI Services’ Compact Crane Fleet

Two Specialized Units: IDI Services maintains two compact cranes specifically for confined space and restricted access applications, ensuring availability for Scotland’s industrial sector and providing backup capacity for critical projects.

Technical Specifications:

- Tracked excavator-based configuration combining mobility with lifting capability.

- Compact dimensions enabling access through standard industrial doorways.

- Full hydraulic boom systems providing precision control and variable reach.

- Load capacities suitable for structural steel, industrial equipment, and heavy components.

- Indoor operation capability with appropriate emissions and noise characteristics.

Operational Advantages:

- Access capability where conventional cranes cannot physically reach.

- Reduced facility modification requirements compared to alternative access solutions.

- Cost-effective solutions avoiding building alterations or equipment dismantling.

- Rapid deployment and repositioning enabling efficient multi-location operations.

- Complete service integration with IDI Services’ comprehensive lifting expertise.

Comprehensive Support Services

Planning and Engineering:

- Detailed facility surveys and access feasibility assessments.

- Load calculations and structural analysis for indoor operations.

- Method statement development specific to confined space lifting.

- Coordination with facility management and production schedules.

Operational Expertise:

- Experienced compact crane operators with industrial facility knowledge.

- Qualified lift supervisors coordinating complex confined space operations.

- Comprehensive rigging capabilities for diverse load configurations.

- Real-time problem-solving adapting to site-specific challenges.

Safety and Compliance:

- Full adherence to confined space regulations and industrial facility requirements.

- Food processing industry standards compliance for hygiene-sensitive environments.

- Comprehensive risk assessment and management procedures.

- Insurance and certification meeting all industry requirements.

Industrial Sector Applications

IDI Services’ compact crane capabilities serve diverse industrial lifting requirements across Scotland:

Structural Projects

- Steel beam replacement and structural modifications.

- Mezzanine installations and multi-level steelwork.

- Building extensions within existing facilities.

- Equipment support structures and mounting frames.

Equipment Installations

- Processing machinery positioning and installation.

- HVAC systems and ventilation equipment.

- Electrical transformers and distribution equipment.

- Control systems and automation infrastructure.

Facility Maintenance

- Component replacement within active production areas.

- Equipment upgrades requiring confined space access.

- Emergency repairs and breakdown response.

- Planned maintenance during scheduled shutdowns.

Diverse Industry Experience

- Food processing and manufacturing facilities.

- Pharmaceutical and chemical production environments.

- Power generation and utilities infrastructure.

- Commercial and industrial building services.

Why Choose IDI Services for Confined Space Lifting

When conventional cranes cannot access your project location, IDI Services provides specialized solutions that deliver results:

Unique Equipment Capabilities

- Two compact cranes providing availability and backup capacity across Scotland.

- Proven access through standard doorways, corridors, and restricted passages.

- Full lifting capability maintained despite compact configuration.

- Indoor operation suitable for diverse industrial environments.

Technical Expertise

- 45+ years of experience solving complex lifting challenges across all sectors.

- Engineering-led approach ensuring optimal solutions for confined space requirements.

- Precision execution achieving exact positioning in challenging environments.

- Comprehensive planning addressing all aspects of restricted access operations.

Safety and Reliability

- Zero-incident culture maintaining highest safety standards in confined space operations.

- Full regulatory compliance meeting industrial facility and sector-specific requirements.

- Professional execution protecting facilities, equipment, and operations throughout projects.

- Proven track record delivering results where access challenges would defeat conventional approaches.

Client-Focused Solutions

- Rapid mobilization responding quickly to industrial facility requirements.

- Flexible scheduling accommodating production windows and maintenance periods.

- Clear communication throughout planning and execution phases.

- Complete service delivery from initial assessment through project completion.

When Conventional Cranes Cannot Reach

Industrial facilities, food processing plants, manufacturing environments, and countless commercial buildings across Scotland present lifting challenges that conventional mobile cranes simply cannot address. Doorways too narrow, ceilings too low, working spaces too confined—these are not obstacles to overcome, but realities that demand different equipment solutions.

IDI Services’ compact crane fleet exists specifically for these scenarios. When your project requires lifting capability inside buildings, through restricted passages, or in spaces where access seems impossible, our specialized equipment provides the solution. With two compact cranes available, we ensure Scotland’s industrial sector has access to confined space lifting expertise when and where it’s needed.

Whether your project involves structural steel replacement, equipment installation, facility maintenance, or any lifting operation in confined or restricted access environments, IDI Services delivers the specialized equipment, technical expertise, and operational excellence that solves challenges conventional approaches cannot address.

For more information on how IDI Services’ compact crane capabilities can solve your confined space lifting challenges, contact our team today.